The Sonnenerde biochar plant

What is charring?

Thermo-chemical conversion processes in which organic compounds are split at high temperatures and largely in the absence of oxygen are called charring. The lack of oxygen prevents complete combustion.

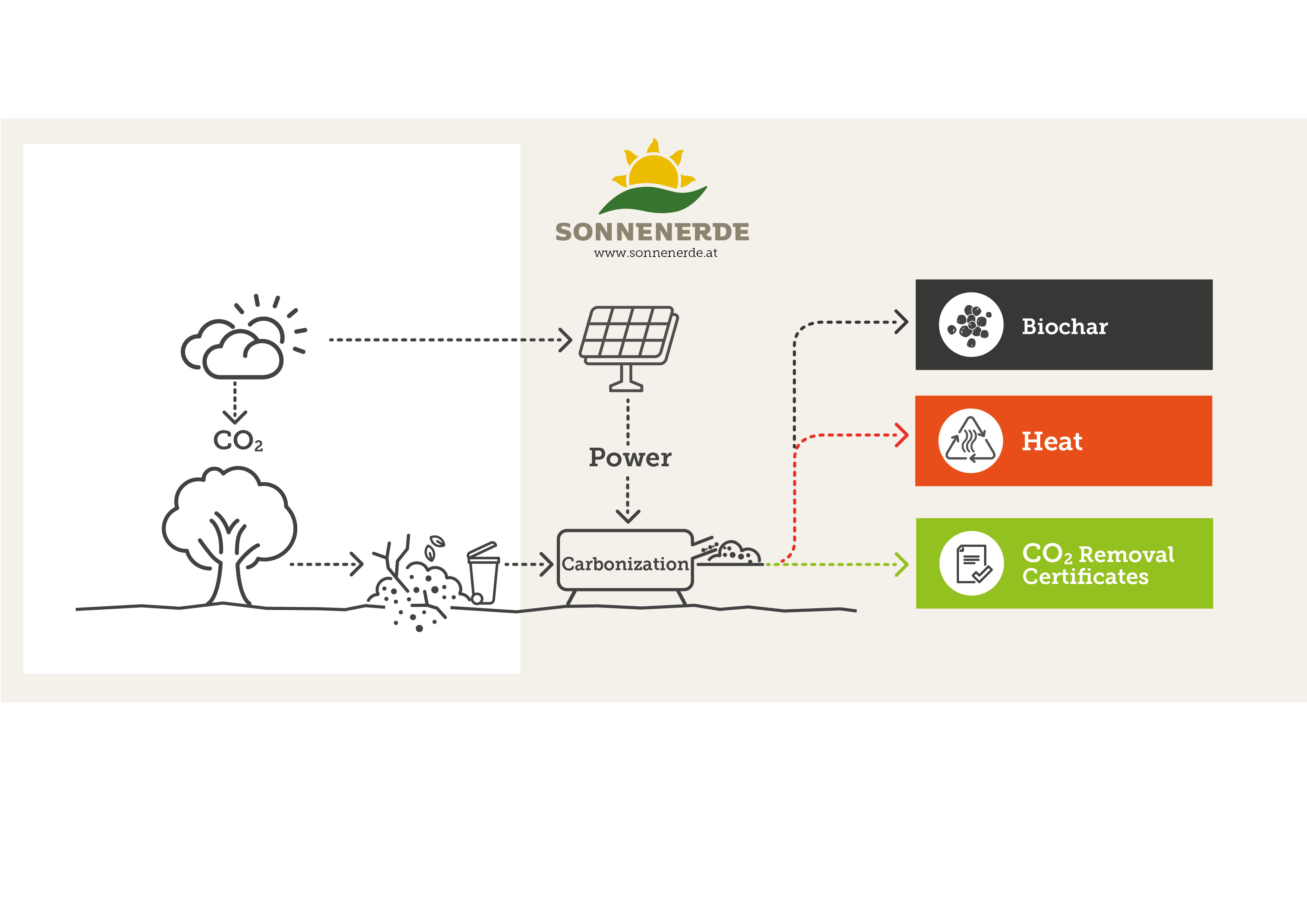

If biomass is charred, about 50% of the carbon compounds are converted into biochar. We produce organic biochar in our charring plant and therefore bind CO2 in the course of production, which results in "negative emissions" and therefore counteracts climate change.

Bigger and better - The new Sonnenerde charring plant for biochar production in Riedlingsdorf

The new Sonnenerde production plant in Riedlingsdorf, Burgenland, is planned to be about 10 times larger than the current plant. For this purpose, we have developed a completely new plant concept. In the past 10 years, around 2,000 tons of biochar have been produced. In the future, it should be possible to produce the same amount within a year.

Invest now in the new Sonnenerde plant and become climate-neutral with CO2 certificates!

Key data of the completely new plant concept:

- Raw material: predominantly woody residues from composting - this closes the cycle and solves the problem of "sieve residue disposal".

- Production output: around 2,000 tons of biochar per year (corresponds to a CO2 binding of around 4,000 tons).

- The aim is to build a CO2-neutral construction of the entire plant - solid wood construction + carbon concrete.

- Largely self-sufficient operation thanks to a photovoltaic system on the roof with a corresponding temporary power storage unit.

- Completely automated, well-planned logistics from raw materials, charring, processing and packaging to the delivery of the finished products.

- Multiple use of the waste heat for contract drying of sewage sludge and subsequent drying of the carbonization raw material.

Innovative charring process

How it works:

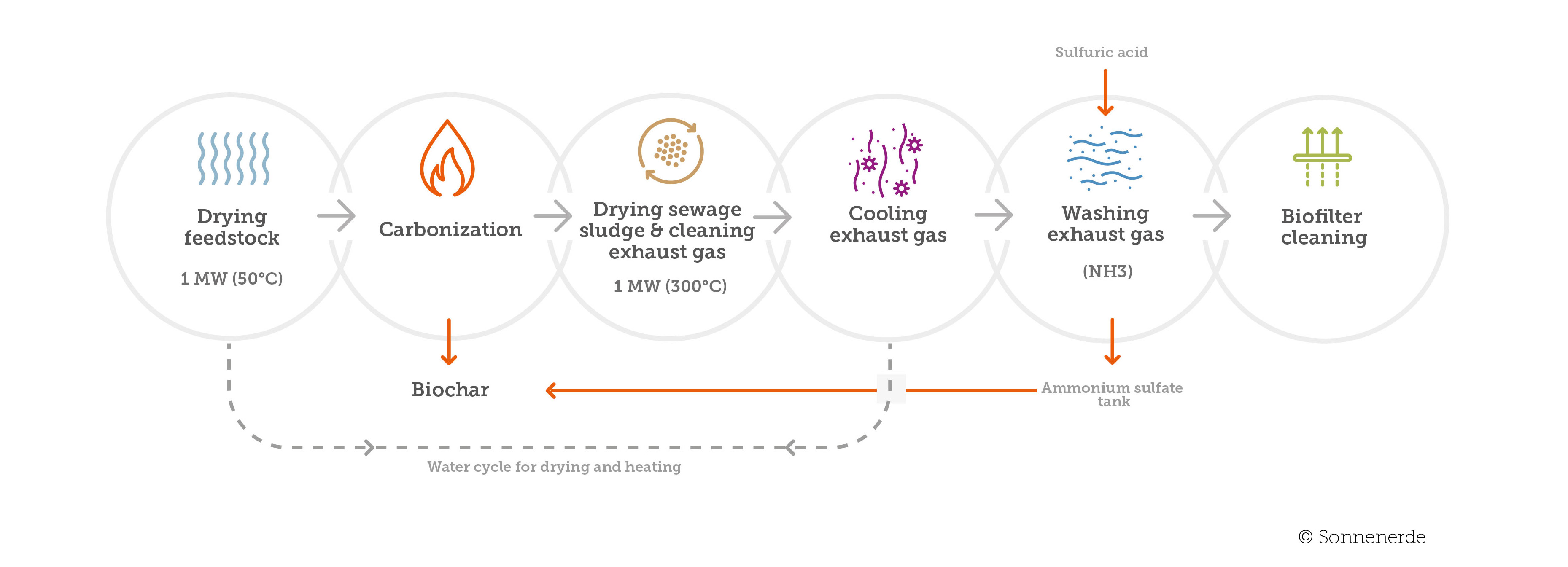

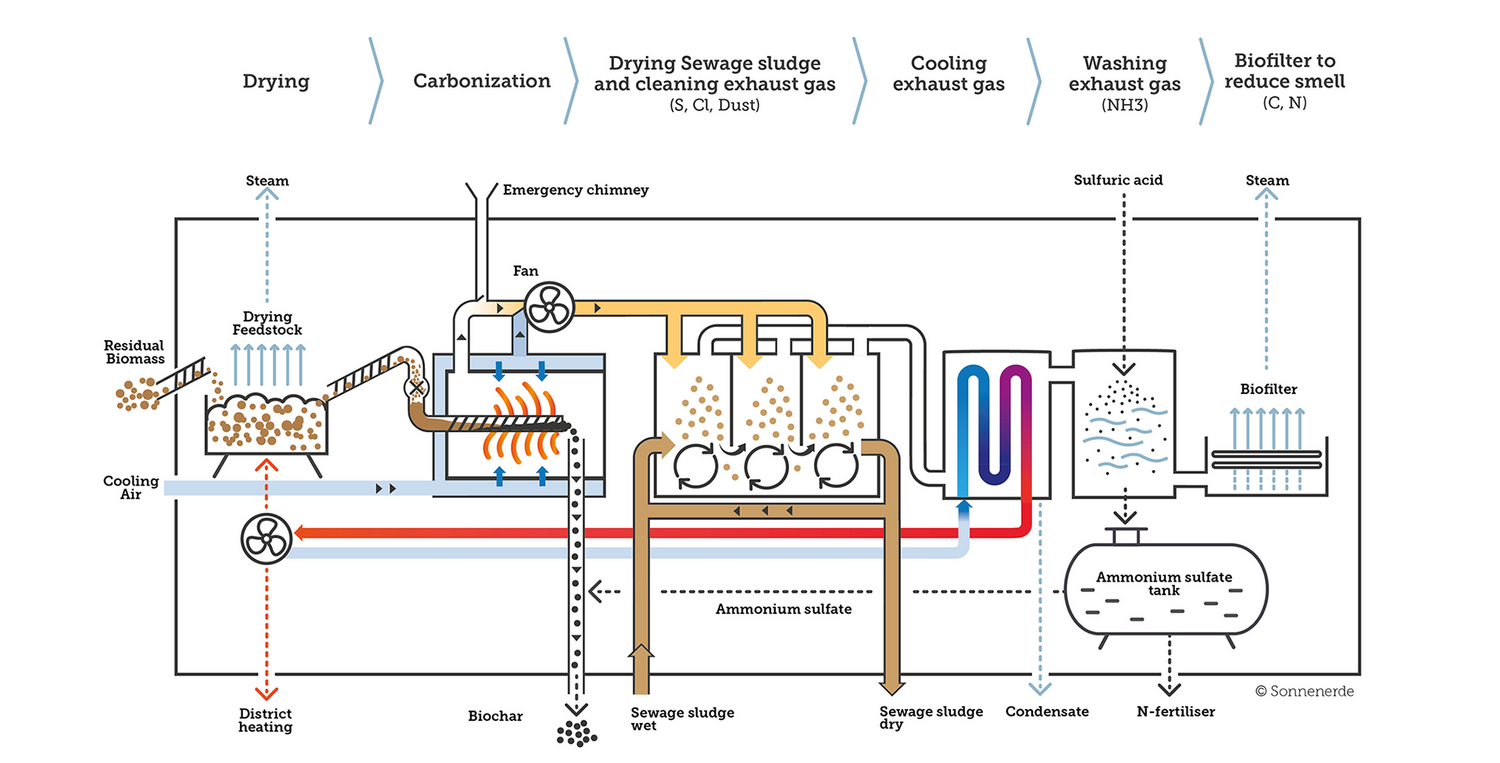

Together with NGE and Jumbo, Sonnenerde has developed a completely new process that has the following advantages compared to others:

- Simplified charring with significantly reduced technology and significantly reduced maintenance.

- Optimized 2-stage heat utilization: Combination with jumbo fluidized bed dryer, subsequent condensation and use as low-temperature heat for drying raw materials and space heating.

- Recovery of nitrogen from sewage sludge drying.

- Emission reduction via final stage biofilter.

Charring as a problem solver

With the Sonnenerde charring process, the sieve residue from composting can also be used as a raw material and converted into high-quality products. At the moment, screen residues have to be disposed of at great expense. Charring not only solves the plastic problem, but also converts this waste into a valuable raw material. Via charring, the minerals adhering to the surface from composting bring with them special properties that are advantageous in further product development.

Our project is a game changer! That's why:

We are very proud that we built the first biochar production plant in Europe to be approved under waste law and which has been in continuous operation since 2012.

The Sonnenerde project is one of the most promising ideas for carbon storage as we achieve optimum results in terms of biochar, raw materials, methods and procedures, economic efficiency and product development. We have been operating a charring plant for organic residues for 10 years and will now implement this longstanding experience into a newly developed large-scale industrial plant.

Purchase CO2 certificates now and become climate-neutral!

New opportunities for investors!

Biochar

- is one of the few recognized carbon storage technologies

- during production, carbon is stabilized and heat energy is obtained

- manufacturing high-quality products that accelerate additional carbon sequestration

- enormous additional benefit in addition to storing carbon --> business model

Raw material

- Wood is a valuable raw material that should be used as a material as much as possible

- Sonnenerde uses sieve residues from composting and woody parts from tree and shrub cuttings. Up until now, it has not been possible to optimally utilize these exclusively organic residues.

- Closing the cycle, improving compost quality

The procedure

- Together with NGE, development of a new, greatly simplified charring technology with significantly lower support costs.

- Charcoal qualities of the highest quality according to the EBC criteria (EBC Feed and EBC Agro Bio).

- In combination with a simplified fluidized bed sludge drying plant, where the exhaust gas from the carbonization can be used directly. This achieves the highest possible heat utilization efficiency and at the same time pre-cleans the exhaust gas.

- Downstream of the dryer the exhaust gas, still at 70 °C, is cooled to 40 °C, condensing the water it contains and thus recovering tits energy. With this low-temperature heat, the charring raw materials are going to be pre-dried and the office and halls heated. So there is double use of heat.

- After the exhaust gas has been cooled down, the nitrogen for coal-loading is obtained via an acidic scrubber.

- After the nitrogen removal, a simple biofilter is completely sufficient for the final cleaning of the exhaust gas.

- There is a very high flexibility of the process with regard to raw materials - wherever heat energy is needed and organic residues are available, this process can be used in the future.

Economic efficiency

- Die Produktionskosten werden durch das neue Verfahren von derzeit rund 1.000 € pro Tonne auf nur mehr 400 € pro Tonne reduziert.

- Für die Kostenreduktion sind mindestens 3 Pyrodry-Linien an einem Standort erforderlich

- Durch die Reduktion der Produktionskosten kann Pflanzenkohle zu einem Massenprodukt für die Landwirtschaft werden

Ready-developed plant charcoal products

- We don't just sequester carbon to bury it: Over the past 10 years Sonnenerde has developed a number of high-demand earth products, such as Terra Preta (organic black soil), fine substrate for city tree planting and a soil activator as a fertilizer.

- Together with the subsidiary CharLine we developed other products such as FeedChar and manure char.

- There is an almost unlimited application potential for the high-quality biochars produced by our process.